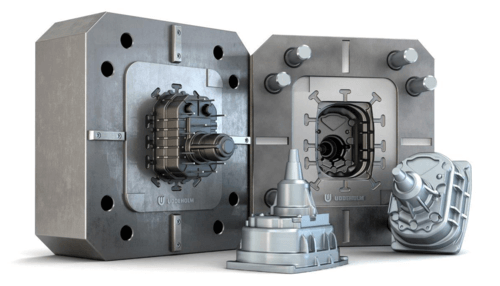

Cable clamps are an indispensable tool for ensuring the integrity of wiring, preventing damage, and facilitating the transmission of power in a dependable manner. Specifically, this is due to the fact that electrical connectivity is becoming increasingly sophisticated across all sectors of operation. The fact that Junying is the most capable Mold Making manufacturer in terms of producing high-quality die casting cable clamps in mass quantities at a price that is cost-effective has become abundantly clear. Junying's objective is to provide support for a wide variety of cable management applications all over the world by continuously upgrading its technology, improving its processes, and adding new capabilities to its product portfolio.

This will allow Junying to meet the ever-changing demands of the market and also provide support for numerous cable management applications.

Across a wide range of industries, Junying has emerged as the supplier of choice for assemblies integrators and equipment original equipment manufacturers (OEMs) due to the capabilities, quality commitment, and economies of scale that it possesses. There are capabilities for customization available. The circular and straight clamp variants that are commonly used are stocked by Junying; however, the company also specializes in the development of custom clamps to meet the specific requirements of individual users, including the following:

Variations in the Parameters:

Alterations can be made to the clamp in accordance with the technical drawings that are provided. These modifications can include adjustments to the clamp's dimensions, thicknesses, tolerances, tightening mechanisms, and other aspects.

The Available Materials:

A variety of alloys, including Zinc Alloy ZA-8, Zinc Alloy ZA-12, and Zinc Alloy ZA-27, as well as Aluminum A360 and A380 alloys, are available for selection, depending on the relative importance of the properties. Provisions are made for screws, bolts, nuts, rubber liners, and connecting terminals in accordance with the requirements of the system interface when it comes to assembly integration. These provisions are made during the assembly integration process. When it comes to low volume production, the utilization of prototyping and sampling allows for the fulfillment of orders that are significantly lower than the typical commercial volume.

The Multiple Iterations of the Design:

Engineers work together in close collaboration to refine designs by evaluating concepts, renderings, and prototypes until the optimal solution is discovered. This process continues until the best solution is found.

Value-Added Components:

Functionality enhancements that are made possible by individualized surface coatings, machined features, and fastening arrangements that are developed according to the requirements of the application are discussed in this article.

Additionally, in order to meet urgent implementation schedules, it is possible to rapidly realize, test, and supply variations that are specific to the customer within a short period of time. Because of the capabilities of the in-house design-making department, this is now feasible. In order to ensure that cable clamps can be precisely optimized for new system configurations or challenging installation scenarios that require innovative form factors that go beyond standard designs, Junyings uses a custom product development process. This process ensures that cable clamps can be precisely optimized.

The Guarantee of Quality and a Variety of Certifications

Several stringent quality management procedures have been implemented by Junying in order to guarantee that cable clamps meet the highest possible quality and consistency requirements. These procedures are as follows:

Materials Evaluation and Certification:In order to guarantee that the raw materials that are utilized are in accordance with the standards that are set by the industry, such as ASTM B85 for aluminum alloys, each and every one of the raw materials is put through a series of chemical and physical examinations. In addition, the evaluation of the respective suppliers is carried out. Critical casting parameters, such as injection pressure and speed, melt temperature, filling time, and so on, are monitored with the assistance of statistical process control (SPC) tools in order to guarantee that the process continues to be stable. This is done within the realm of statistical process control. Precision gauges and testing equipment are utilized throughout the various stages of the manufacturing process in order to conduct inspections of components for defects, dimensions, and material properties.

"In-process inspection" is the name given to this particular kind of inspection. Following the completion of the manufacturing process, the components are put through final testing, which consists of dimensional checks performed with a computerized measurement machine (CMM) and visual inspection, in addition to sample destructive physical analysis for the purpose of microstructural validation.

The Certification of Products:Cable clamps that are designed for use in Europe, the United States, and other regions have been certified as ROHS, REACH, and UL, respectively, in order to support compliance with global market standards. These certifications were obtained in order to ensure international compliance.

Containerization and Labeling:The products are packaged with great care to prevent damage during shipping, and they are labeled with the part number, details of the purchase order, the quantity, and information about the manufacturer. The Control of Documents -In order to fulfill the prerequisites of the ISO 9001 standard, quality records are maintained. These records consist of material certification, inspection reports, testing documentation, and certification proofs. The quality management system of Junyings has been certified to the ISO 9001:2015 standard on an annual basis by a third-party registrar that is internationally recognized. In order to guarantee that the system is always in accordance with the standards, this certification has been brought into existence. When these checkpoints are adhered to in a stringent manner, it ensures that the cable clamps that are shipped out to customers are free of defects and meet the quality, reliability, and safety standards that are desired during the manufacturing process.

Obtaining certifications provides one with additional benefits, one of which is access to regulated industries.

Services Relating to Warehousing and Logistics

Junying ensures that the Mold Making manufacturer of standardized wire clamps is able to meet the typical order volumes by utilizing just-in-time production and replenishment throughout the manufacturing process. When scheduling special orders, the lead times that have been agreed upon are taken into consideration. For the purpose of storage, the finished goods warehouse adheres to the first-in, first-out (FIFO) policy. Batches are identified, and the expiration date of the shelf life, if applicable, is also taken into consideration. When it comes to alloy castings, both the temperature and the humidity are taken into consideration and managed. A fleet of delivery vehicles that are owned and operated by the company itself, in addition to partnerships with major logistics providers such as DHL, Fedex, UPS, and others, ensures that products are delivered on time to customer locations all over the world. When using sea freight, it is possible to transport large orders across continents in containers that range in length from twenty to forty feet. The use of air freight for the delivery of smaller consignments that need to be delivered immediately through airportsTransportation of goods on the ground within countries, either directly or through the use of distributors either directly or indirectlyIn accordance with the mode of transportation and the specifications of the customer, the packaging is tailored to meet their specific needs.

The use of an enterprise resource planning system (ERP) for freight forwarding with real-time order trackingEvery single shipment is covered by insurance, and the amount of coverage is determined by the declared value. The inventory that is currently in quarantine and is kept in regional warehouses at this timeProvide assistance with the necessary documentation for the clearance of customsIn order to fulfill its commitments to deliver products on time to customers located all over the world, Junying is able to do so thanks to its well-established logistical operations. Customers are able to rely on wire clamps to be acquired from stock or in accordance with the production dates that have been scheduled without any delays occurring.