When you think about aerospace engineering, it’s easy to overlook the critical role of industrial gearboxes. These components are essential for transmitting power from engines to various systems, ensuring everything operates smoothly and efficiently. You might not realize how the selection of a specific gearbox type can drastically affect an aircraft’s performance and fuel efficiency. As you consider their impact on both comfort and safety, it raises questions about the future of gearbox technology in aviation. What innovations are on the horizon that could transform this vital aspect of aerospace engineering?

Understanding Industrial Gearboxes

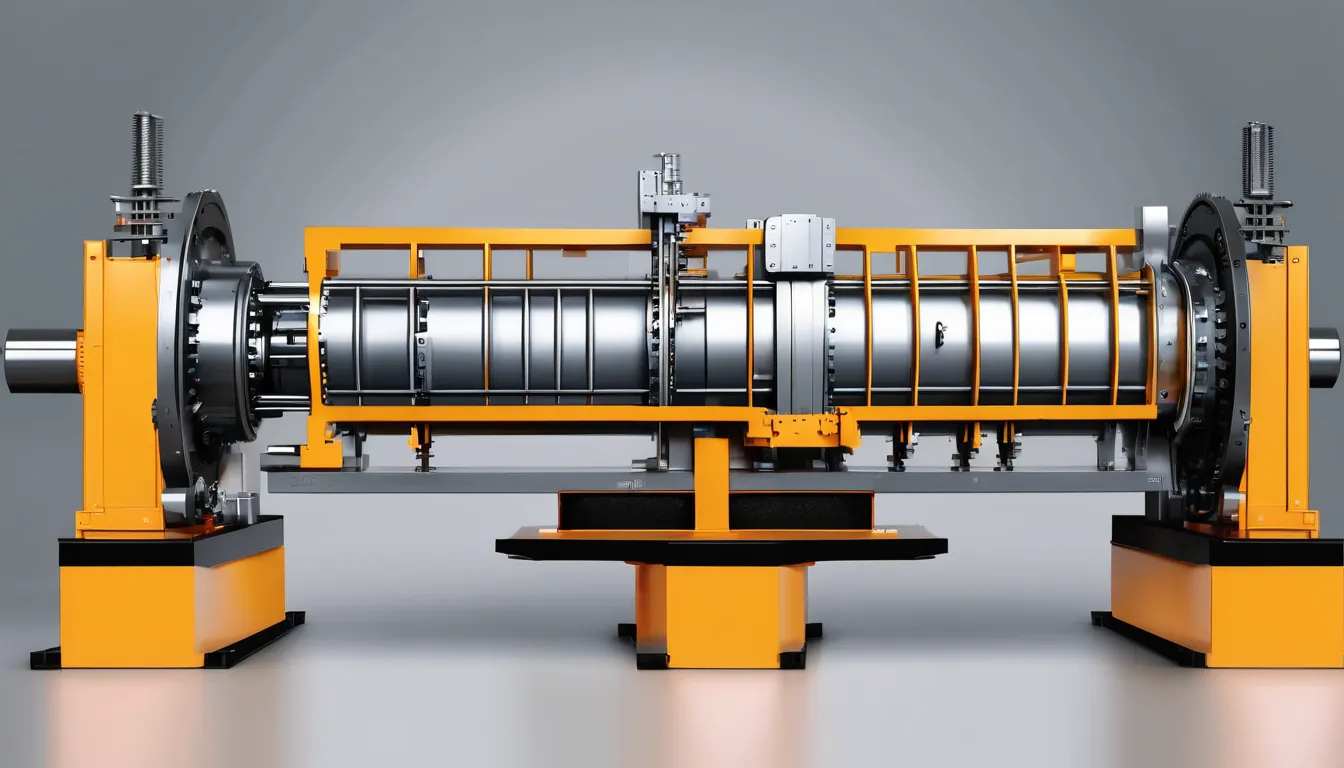

Understanding industrial gearboxes is crucial for anyone involved in aerospace engineering. These mechanical devices play a vital role in converting input speed and torque into a usable output, which is essential for various aerospace applications.

You’ll find that gearboxes help optimize the performance of engines, actuators, and other critical systems, ensuring efficiency and reliability.

When you delve into gearboxes, you’ll encounter different types, such as planetary, helical, and bevel gearboxes. Each type has unique characteristics that make it suitable for specific aerospace functions.

For instance, planetary gearboxes are often favored for their compact design and high torque density, while helical gearboxes offer smooth operation and low noise levels.

In addition to understanding the types, you should also consider factors like material selection, load capacity, and lubrication methods. These elements significantly impact the gearbox’s lifespan and performance in demanding aerospace environments.

Key Functions in Aerospace Applications

Industrial gearboxes play several key functions in aerospace applications, each critical for the overall performance and safety of aircraft systems. One of the main roles you’ll notice is their ability to transmit power efficiently from engines to various components, like the propellers or rotors. By optimizing torque and speed, gearboxes ensure that your aircraft operates smoothly and effectively.

Additionally, these gearboxes help manage the load and distribute power evenly across different systems, which is essential for maintaining stability and control during flight. They also play a significant role in reducing vibrations and noise, contributing to a more comfortable and safer experience for both pilots and passengers.

Another important function is the ability to provide gear reduction, which is vital for controlling the aircraft’s speed and maneuverability. In high-stress environments, gearboxes act as a protective barrier, absorbing shocks and minimizing wear on other components.

Types of Gearboxes Used

In aerospace engineering, various types of gearboxes are employed to meet specific performance requirements and operational demands. You’ll find that each type serves a unique purpose, enhancing the efficiency and reliability of aircraft systems.

Here’s a quick overview of some common gearbox types used in aerospace applications:

| Gearbox Type | Application | Benefits |

|---|---|---|

| Planetary Gearbox | Engine power transmission | Compact design, high torque density |

| Helical Gearbox | Landing gear systems | Smooth operation, low noise |

| Bevel Gearbox | Control surfaces | Change direction of motion effectively |

| Spur Gearbox | Auxiliary systems | Simple design, easy to manufacture |

Each gearbox type has its own set of advantages that make it suitable for specific applications within the aerospace sector. By understanding these differences, you can better appreciate how gearboxes contribute to the overall performance and safety of aircraft. Whether it’s for power transmission or controlling movements, the right gearbox is crucial to achieving optimal results in aerospace engineering.

Impact on Aircraft Performance

The choice of gearbox directly influences aircraft performance, impacting everything from fuel efficiency to control responsiveness. When you select the right gearbox, you enhance the engine’s power transmission, leading to optimal thrust and acceleration. This means your aircraft can achieve higher speeds and climb more efficiently, reducing overall flight times.

Moreover, a well-designed gearbox minimizes energy loss, which directly translates to improved fuel efficiency. You’ll find that a lightweight, high-performance china gearbox manufacturer allows for longer flights with less fuel, a critical factor in today’s aviation industry focused on sustainability.

Control responsiveness is another vital area where gearboxes play a key role. The gearbox connects the engine to control surfaces, ensuring precise movements and stability during flight.

If there’s a lag or inefficiency in the gearbox, you’ll notice it in how your aircraft handles, potentially compromising safety and maneuverability.

Future Trends in Gearbox Technology

Emerging trends in gearbox technology are set to revolutionize the aerospace industry, focusing on increased efficiency and reduced weight. You can expect innovations that integrate advanced materials, such as composites and lightweight alloys, to enhance performance while minimizing mass. Furthermore, the shift toward electric and hybrid propulsion systems will drive the development of gearboxes designed for high torque and compact configurations.

Here’s a quick overview of some key trends:

| Trend | Description | Impact on Aerospace |

|---|---|---|

| Advanced Materials | Use of composites and lightweight alloys | Reduced weight and enhanced durability |

| Smart Gearbox Technologies | Integration of IoT for predictive maintenance | Increased reliability and reduced downtime |

| Modular Design | Flexible configurations for various applications | Easier maintenance and upgrades |

| Enhanced Lubrication | Development of self-lubricating systems | Lower maintenance costs and improved efficiency |

| Sustainable Practices | Focus on eco-friendly manufacturing processes | Reduced environmental impact |

These advancements will not only improve aircraft efficiency but also pave the way for new designs and capabilities, making the future of aerospace engineering even more exciting.

Conclusion

In conclusion, industrial gearboxes are essential in aerospace engineering, playing a vital role in power transmission and aircraft performance. By optimizing torque, speed, and load distribution, they enhance stability, control, and passenger comfort. With advancements in technology, future gearbox innovations promise even greater efficiency and reliability. As you continue to explore this field, you’ll see how these components are crucial for the ongoing evolution of aircraft design and performance.

No Comments